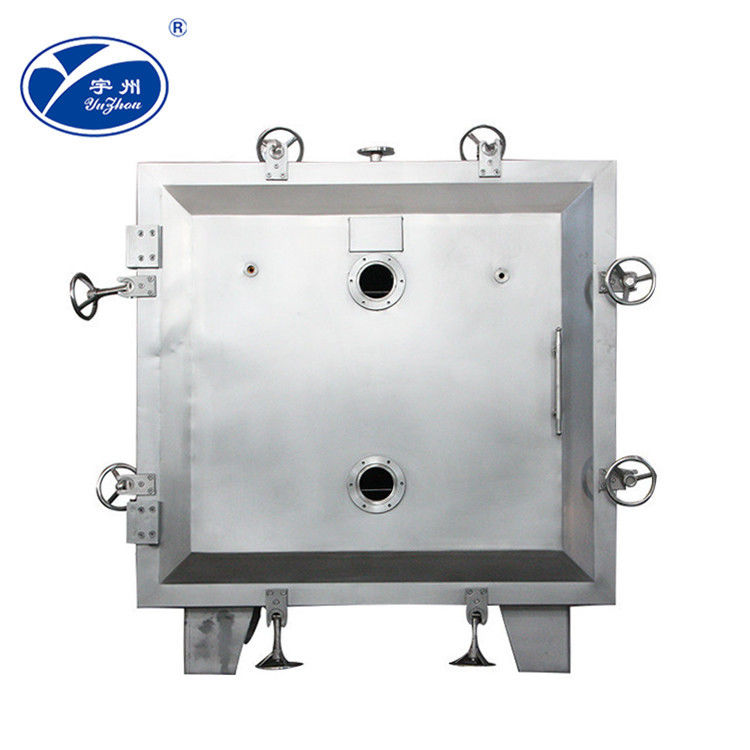

SUS316L 8 trays Industrial Vacuum Dryer Steam / Hot Water Heating

Product Details:

| Place of Origin: | China |

| Certification: | SGS, CE, ISO |

| Model Number: | FZG |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1unit |

|---|---|

| Price: | USD10990-59000/unit |

| Packaging Details: | shipping container |

| Delivery Time: | 35 working days |

| Payment Terms: | L/C, D/A, D/P, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 1000unit per year |

|

Detail Information |

|||

| Name: | Vacuum Tray Dryer | Material: | SUS 304, SUS316L |

|---|---|---|---|

| Type: | Static Drying | Tray Number: | 8-96 |

| Heating Source: | Electricity, Hot Water Or Steam | Packing: | 40HQ Container |

| Temperature: | 30-120 | ||

| Highlight: | 8trays Industrial Vacuum Dryer,SUS316L Industrial Vacuum Dryer |

||

Product Description

Custom Industrial Vacuum Dryer Drying Machine Steam / Hot Water Heating

I. Overview:

Industrial vacuum dryer is suitable for drying and solvent recovery of raw materials in pharmaceutical chemistry and other industries, supporting its reasonable system configuration, reliable control system, and greatly improving equipment safety and economy. The entire system is designed and manufactured in accordance with the 2010 GMP requirements (China).

Second, the main purpose:

1. The industrial vacuum dryer is based on the principle that the boiling temperature of water is low under low pressure, so that the moisture in the dried aqueous material is rapidly vaporized and discharged to achieve the purpose of puffing and drying. Compared with the ordinary drying method, the drying speed is fast. The utility model has the advantages of small energy consumption, low temperature, low pollution and no damage to the inherent physical properties of the dried articles.

Third, the equipment features:

1. The vacuum drying period box is a box structure, the inner tank of the oven and the heating plate layer. The baking plates are all made of SUS316L stainless steel, the outer plate is made of SUS304, the middle is filled with thermal insulation cotton, the heating plate layer is installed separately, and there is no dead angle in the cavity. The temperature control is precise, easy to maintain, easy to disassemble, and each layer can be online "CIP", which is heated by hot water or heat transfer oil.

2, the heating plate layer can withstand pressure 0.5MPa, vacuum chamber pressure -0.1MPa

3, vacuum chamber and layer design temperature 0 ~ 145 ° C

4. There is a heating plate layer on the upper part of the vacuum chamber.

5. The outside of the vacuum chamber is strengthened by steel

6, with on-site LCD temperature online display

7, nitrogen injection pipeline system

8, electrical cabinet

Techinical specification:

| Model Name | YZG-600 | YZG-800 | YZG-1000 | YZG-1400A | FZG-10 | FZG-15 | FZG-20 | |

| Inter size of drying chamber(mm) | Φ600×976 | Φ800×1247 | Φ1000×1527 | Φ1400×2054 | 1500×1060 ×1220 | 1500×1400 ×1220 | 1500×1800 ×1220 | |

| Outer size of drying chamber(mm) | 1135×810 ×1024 | 1700×1045 ×1335 | 1693×1190 ×150 | 2386×1675 ×1920 | 1513×1924 ×1720 | 1513×1924 ×2060 | 1513×1924 ×2500 | |

| Layers of baking support | 4 | 4 | 6 | 8 | 5 | 8 | 12 | |

| Interval of baking(mm) | 82 | 82 | 102 | 102 | 122 | 122 | 122 | |

| Size of baking tray(mm) | 310×600 ×45 | 520×410 ×45 | 520×410 ×45 | 460×640 ×45 | 460×640 ×45 | 460×640 ×45 | 460×640 ×45 | |

| Quantity of baking tray | 4 | 8 | 12 | 32 | 20 | 32 | 48 | |

| working pressure inside the pipe of baking support(Mpa) | ≤0.784 | ≤0.784 | ≤0.784 | ≤0.784 | ≤0.784 | ≤0.784 | ≤0.784 | |

| Operation temperature of baking support, oC | 35-150 | 35-150 | 35-150 | 35-150 | 35-150 | 35-150 | 35-150 | |

| Degree of vacuum inside the chamber when operation (Mpa) | -0.09~0.096 | |||||||

| Under the condition of -0.1Mpa and 110oC,evaporation rate of water(kg/m2.hr ) | 7.2 | 7.2 | 7.2 | 7.2 | 7.2 | 7.2 | 7.2 | |

| When condenser is used,Model,and power of vacuum pump(kw) | 2X-15A 2KW | 2X-30A 3KW | 2X-30A 3KW | 2X-70A 5.5KW | 2X-70A 5.5KW | 2X-70A 5.5KW | 2X-90A 2KW | |

| When condenser is not used,Model,and power of vacuum pump(kw) | SK-0.8 2.2KW | SK-2.7 4KW | SK-3 5.5KW | SK-6 11KW | SK-3 5.5KW | SK-6 11KW | SK-6 11KW | |

| Weight of drying chamber(kg ) | 250 | 600 | 800 | 1400 | 1400 | 2100 | 3200 | |