Addtive Powder Dryer , Industrial 50 - 120KG/Batch Pellet Dryer Machine

Product Details:

| Place of Origin: | China |

| Certification: | SGS, CE, ISO |

| Model Number: | GFG-120 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1unit |

|---|---|

| Price: | USD10990-59000/unit |

| Packaging Details: | shipping container |

| Delivery Time: | 35 working days |

| Payment Terms: | L/C, D/A, D/P, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 1000unit per year |

|

Detail Information |

|||

| Name: | Fluid Bed Dryer | Material: | SUS 304, SUS316L |

|---|---|---|---|

| Temperature: | 30-200 | Evaporation Capacity: | 50-120KG/HOUR |

| Heating Source: | Electricity Or Steam | Packing: | 40HQ Container |

| Standard: | GMP | Finish: | Brush Finish |

| Highlight: | vfbd dryer,50KG/H vfbd dryer,120KG/H pellet dryer machine |

||

Product Description

GFG high efficient fluid bed dryer for sodium benzoate, addtive powder

Addtive Powder Industrial Fluid Bed Dryers Evaporation Capacity 50 - 120KG / HOUR

Industrial fluid bed dryers Main feature

The material container adopts cylinder jacking seal, rapid, easy to operate and reliable.

The bed is set in a stirring, quick and convenient.

No dead angle, good fluidization, fast drying speed, thorough cleaning, no cross-contamination. Sealed operation, no dust flying, in line with the GMP standard

Application

Industrial Fluid bed dryer is used for drying food powder or granules, chemical powder drying, powder drying. For the boiling drying of granular materials, the size is 0. 1-6mm, suitable for fast drying of finished products, intermediate (semi-finished) in such industries as aspharmaceutical, food, light industry and chemicals etc.

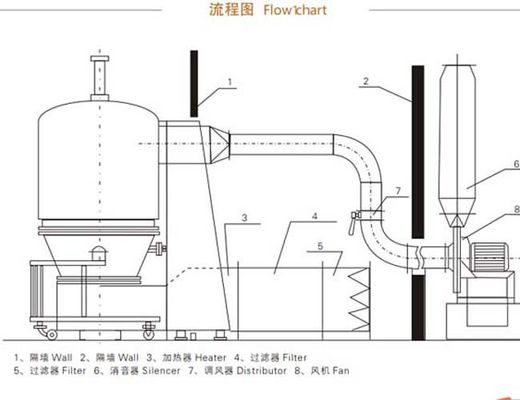

Working principle

Used the draught of fan, natural air flows through purifying cabinet, heater and froms high speed air flow in the hole of material bed, which makes the material into boiling(fluidized)status, during the large area touch between gas and solid phases, mosture of material is veaporated quickly, and thus reaching the purpose of drying.

| Item | Model | |||||||||

| GFG-60 | GFG-100 | GFG-120 | GFG-150 | GFG-200 | GFG-250 | GFG-300 | ||||

| Volume of hopper | Liter | 200 | 300 | 400 | 500 | 650 | 800 | 1000 | ||

| Production capacity | kg/batch | 30-60 | 50-100 | 60-120 | 70-150 | 100-200 | 120-250 | 150-300 | ||

| Air inlet temperature | 0C | 50-100 | ||||||||

| Fan | Blast | M3/h | 2576 | 3488 | 3619 | 5114 | 5153 | 6032 | 7185 | 7766 |

| Air pressure | Pa | 5639 | 5080 | 7109 | 5869 | 9055 | 7610 | 7400 | 7218 | |

| Motor power | kw | 7.5 | 11 | 11 | 15 | 18.5 | 22 | 22 | 30 | |

| Agitator | Speed | r/min | 11 | 11 | 11 | 11 | 11 | 11 | 11 | |

| Motor power | kw | 0.55 | 1.1 | 1.1 | 1.5 | 1.5 | 2.2 | 2.2 | ||

| Steam | Pressure | Mpa | 0.4 | 0.4 | 0.4 | 0.4 | 0.6 | 0.6 | 0.6 | |

| Consumption | kg/h | 140 | 170 | 210 | 240 | 230 | 280 | 280 | ||

| Compressed air | Pressure | Mpa | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | |

| Consumption | m3/h | 0.6 | 0.6 | 0.6 | 0.9 | 0.9 | 0.9 | 0.9 | ||

| Weight of main frame | kg | 1000 | 1200 | 1200 | 1500 | 1700 | 2000 |

2200

|

||

1, need to strengthen the sealing effect of the boiling dryer, such as the current more than most of the boiling dryer plane flange to connect the dryer hopper and equipment body, the sealing effect is poor, can be replaced with concave and convex surface flange connection.

2, Dryer heat exchanger Most of the use of steel tube winding fin, although the cost of material savings, but poor heat exchange effect, the proposed use of copper tube for heat exchange, although the cost is higher, but in the long run, can save a lot of energy consumption. 3, increase the insulation measures can effectively prevent the loss of heat, most of the oven drying box is used to conserve heat, such as vacuum drying box, electric blast drying oven, hot air circulation ovens and other drying equipment.