Centrifugal Pressure Spray Dryer , SUS304 Egg Powder Spray Drying Equipment

Product Details:

| Place of Origin: | China |

| Certification: | SGS, CE, ISO |

| Model Number: | LPG-10 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1unit |

|---|---|

| Price: | USD10990-59000/unit |

| Packaging Details: | shipping container |

| Delivery Time: | 25 working days |

| Payment Terms: | L/C, D/A, D/P, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 1000unit per year |

|

Detail Information |

|||

| Name: | Spray Dryer | Material: | SUS304, SUS316L |

|---|---|---|---|

| Nozzle: | Centrifugal Atomizer | Evaporation Capacity: | 10KG/HOUR |

| Heating Source: | Electricity | Packing: | 20GP Container |

| Highlight: | Centrifugal pressure spray dryer,SUS304 spray drying equipment |

||

Product Description

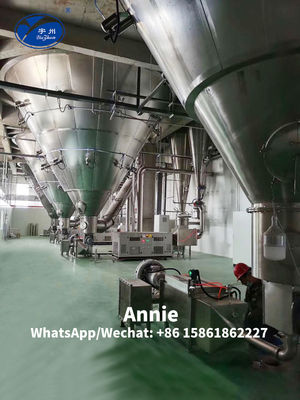

High Speed Centrifugal Pressure Spray Dryer For Egg Powder Stable Performance

High speed centrifugal spray dryer instructions

The LPG high speed centrifugal spray dryer is suitable for emulsions, suspensions, pastes and liquid solutions. In polymers and resins, fuels, paints, ceramics, glass, detergents, pesticides, carbohydrates, dairy products, detergents and surfactants, fertilizers, organic compounds and inorganic compounds of dry materials, especially in inorganic compounds Significant. The dryer can be widely used in pharmaceutical, chemical, food and other industries/areas

Principle of high speed centrifugal spray dryer

Air flows through the filter, the heater and dryer enter the top of the distributor, and a spiral of hot air enters the dryer evenly. The leaf grass feed from the filter is expected to pump the centrifugal atomizer on top of the dryer, spray the liquid into very small droplets, feed and hot air flow and contact, rapid evaporation of water, drying in a short time - Finished and finished products from the bottom drying tower and cyclone, exhaust from the fan

Features and application drying speed, material liquid by centrifugal spray, surface area greatly increased, in the high temperature airflow, instantaneous evaporation 95%-98% moisture, complete drying time only a few seconds.

Suitable for heat-sensitive materials, because the droplet and hot air flow direction, although the hot air temperature is higher, but the material in the water evaporation will not overheat, the temperature distribution in the drying tower is shown below the left. The use of a wide range of material with a large number of different materials are used in this production.

such as polymers and resins, dyes, pigments, ceramics, glass, rust inhibitors, insecticidal drugs, carbohydrates, dairy products, blood and fish products, fertilizers, organic, chemical compounds and so on. The product has good dispersion, fluidity and solubility.

This is due to the instant completion of drying, the product can maintain a homogeneous fine granular. The production process is simplified and the operation control is convenient. For wet content (special materials up to 90%) of the solution can be dried into a powder product, after drying no more crushing and screening, reducing the production process, improve product purity. For product size, pine density, moisture, in a certain range, can change the operating conditions to adjust, control, management is very convenient.

![]()

FAQ

This spray drier is widely used in chemical industry, pharmaceutical industry, foodstuff industry and so on.

1. Material name

2. Content of solid; Content of moisture(%)

3. Processing capacity; Evaporation capacity? (kgs/hour; Litre/ hour)

4. Max. Temperature the material can bear

5. Heating source. Do you need Electric heating compensation to improve heating temperature?

Spray dryer TECHNICAL PARAMETERS spray dryer

| Spray dryer Parameter |

LPG -5 |

LPG -10 |

LPG -15 |

LPG -20 |

LPG -25 |

LPG -50 |

LPG -100 |

LPG -150 |

LPG -200 |

LPG -500 |

LPG -800 |

LPG -1000 |

LPG -2000 |

LPG -3000 |

LPG -4500 |

LPG -6500 |

| Inlet temperature(°C) | 140-350automaticallycontrolled | |||||||||||||||

| Outlet temperature(°C) | 80-90 | |||||||||||||||

| Water evaporation capacity(kg/h) | 5 | 10 | 15 | 20 | 25 | 50 | 100 | 150 | 200 | 500 | 800 | 1000 | 200 | 3000 | 4500 | 6500 |

| Diameter of atomizing tray (rpm) | 50 | 80 | 80 | 120 | 150 | 180-210 | Decidedin accordance witn the requirementsof processs | |||||||||

| Max Electric heating power(kw) | 12 | 24 | 36 | 45 | 46 | 63 | 81 | 99 | ||||||||

| Dried powder restoring rate(%) | ≥95 | |||||||||||||||

| Length of convered area (m) | 1.6 | 2.7 | 3 | 3.5 | 4 | 4.5 | 5.2 | 7 | 7.5 | 12.5 | 13.5 | 14.5 | Decided in accordance the flow chart, | |||

| Width of convered area (m) | 1.1 | 1.5 | 1.8 | 2 | 2.7 | 2.8 | 3.5 | 5.5 | 6 | 8 | 12 | 14 |

Condition of filed and requirements

|

|||