Rotary Vibro Screen Separator , 3 Layers GMP Industrial Powder Sifter

Product Details:

| Place of Origin: | China |

| Certification: | SGS CE ISO |

| Model Number: | RFT |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1units |

|---|---|

| Price: | USD1490-9900 per unit |

| Packaging Details: | plywood |

| Delivery Time: | 7 working days |

| Payment Terms: | Western Union, MoneyGram |

| Supply Ability: | 10000units per year |

|

Detail Information |

|||

| Name: | Circular Vibrating Screen | Application: | Power, Granule , Liquid |

|---|---|---|---|

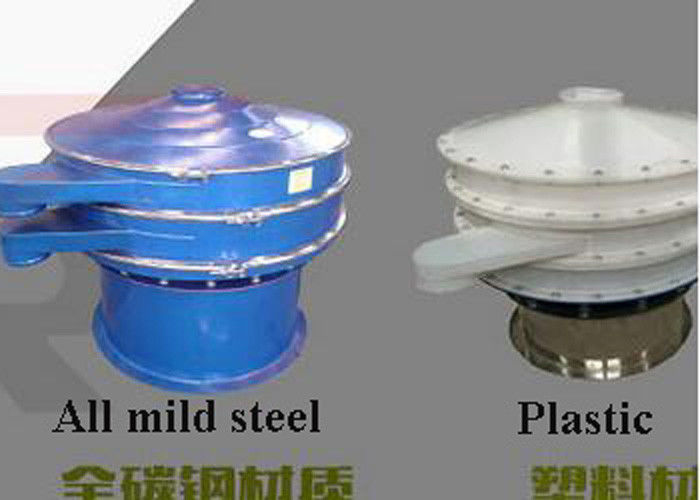

| Layer: | 1-4layers | Material: | Stainless Steel 304 Or 316L |

| Application Industries: | Food, Chemical, Pharma, Etc | Voltage: | 110 220 380 400 415 |

| Highlight: | GMP vibro screen separator,3Layers industrial powder sifter |

||

Product Description

Rotary Vibro Screen Separator , 3 Layers Industrial Powder Sifter GMP Standard

Rotary vibrating screen is a high-precision fine powder screening machine with low noise and high efficiency. It takes 3-5 minutes to change the net quickly. It is fully enclosed and suitable for screening and filtering of particles, powder and mucilage. The vibrating screen is made up of an upright motor as an excitation source. The upper and lower ends of the motor are equipped with an eccentric weight to convert the rotary motion of the motor into a horizontal, vertical, and inclined three-dimensional motion, and then transmit this motion to the screen surface. . Adjusting the phase angle of the upper and lower ends can change the trajectory of the material on the screen surface.

Rotary vibrating screen Function and principle

The basic principle is to convert the rotary motion of the motor into a horizontal, vertical, and inclined three-dimensional motion by the weight (unbalanced weight) installed on the upper and lower ends of the motor shaft, and then transmit this motion to the screen surface. Changing the phase angle of the upper and lower weights can change the direction of travel of the material.

Rotary vibrating screen Features

1) Unique screen structure design, convenient and quick replacement of the screen (5 to 10 minutes), in addition to this design

Various screens (nylon, special dragon, PP net) are allowed.

2) Screen machine design; compact and easy to assemble, one person can operate the screen machine.

3) Compared with other related brand manufacturers, it has a large screening area and high efficiency processing capacity.

4) The mother net fully supports the fine mesh, so the fine mesh can have a long life, and the use of the fine mesh consumables can be reduced, and the long-term production process can reduce the cost.

| Model | Layer | Power(KW) | Mesh diameter(mm) | Dimension(mm) |

| RFT-400 | 1S | 0.18 or 0.37 | 360 | 720x430x600 |

| 2S | 720x430x690 | |||

| 720x430x780 | ||||

| 3S | ||||

| RFT-600 | 1S | 0.37 or 0.55 | 560 | 600x600x740 |

| 2S | 600x600x880 | |||

| 3S | 600x600x1020 | |||

| RFT-800 | 1S | 0.55 or 0.75 | 760 | 800x800x840 |

| 2S | 800x800x1000 | |||

| 3S | 800x800x1160 | |||

| RFT-1000 | 1S | 0.75 or 1.1 | 930 | 970x970x950 |

| 2S | 970x970x1110 | |||

| 3S | 970x970x1270 | |||

| RFT-1200 | 1S | 1.1 or 1.75 | 1130 | 1170x1170x1090 |

| 2S | 1170x1170x1250 | |||

| 3S | 1170x1170x1410 | |||

| RFT-1500 | 1S | 1.5 or 2.2 | 1430 | 1470x1470x1110 |

| 2S | 1470x1470x1270 | |||

| 3S | 1470x1470x1430 |

Want to Know more details about this product