Professional High Speed Laboratory Spray Dryer for Chemicals Processing

Product Details:

| Place of Origin: | Jiangsu, China |

| Brand Name: | yuzhou |

| Certification: | ISO14001 ISO9001 |

Payment & Shipping Terms:

| Price: | $14,000.00/Sets 1-9 Sets |

|---|---|

| Packaging Details: | plywooden case,wooden case,or make it as u requirement |

| Supply Ability: | 20 Set/Sets per Month Professional high speed laboratory spray dryer price |

|

Detail Information |

|||

| Type: | Spray Drying Equipment | Application: | Medicine Processing, Chemicals Processing, Plastics Processing, Food Processing, Food Chemical Pharmaceutical |

|---|---|---|---|

| Power: | According To The Actual Sitation | After-sales Service Provided: | Online Support, Video Technical Support, Free Spare Parts, Field Installation, Commissioning And Training, Field Maintenance And Repair Service, Engineers Available To Service Machinery Overseas |

| Weight (KG): | 500 | After Warranty Service: | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service |

| Applicable Industries: | Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Farms, Retail, Energy & Mining, Food & Beverage Shops | Heating Source: | Natural Gas Electricity,oil,gas |

| Capacity: | According To The Actual Sitation | Installation: | Under Technician's Guidance |

| Highlight: | ISO14001 Laboratory Spray Dryer,Chemicals Processing Laboratory Spray Dryer |

||

Product Description

Chemicals Processing Professional High Speed Laboratory Spray Dryer Price

|

spec

|

|

ZPG-25

|

ZPG-50

|

ZPG-80

|

ZPG-100

|

ZPG-150

|

ZPG-200

|

ZPG-300

|

|

evaporation capacity(kg/h)

|

|

25

|

50

|

80

|

100

|

150

|

200

|

300

|

|

process amount of material liquid(kg/h)

|

25-34

|

50-68

|

80-108

|

100-135

|

150-203

|

200-270

|

300-406

|

|

|

output of finished pcoduct(kg/h)

|

|

4.8-7.2

|

9.2-14

|

14.8-22.4

|

18.4-28

|

24-42

|

36.8-56.4

|

55-85

|

|

solid content of material liquid( %)

|

|

|

|

18-30

|

|

|

|

|

|

moisture content of finished product( %)

|

|

|

|

3-5

|

|

|

|

|

|

electric power(kw)

|

|

63

|

|

132

|

153

|

204

|

246

|

330

|

|

heat source

|

|

|

|

Steam pius electricity

|

|

|

||

|

Collecting method of product and its efficiency

|

|

Grade one or two or three stage cyclone wet dust remover is greater than or equal to 95%

|

||||||

|

automatic control meters and instruments

|

indicator of not air and exhaust air temperature

|

|||||||

|

temperature of air inlet(℃)

|

|

160-220

|

||||||

|

temperature of air outlet(℃)

|

|

80-100

|

||||||

|

|

L

|

7000

|

8000

|

9800

|

11000

|

12200

|

14100

|

15000

|

|

overal dimensions(mm)

|

W

|

4000

|

5000

|

5700

|

6200

|

7000

|

7800

|

9000

|

|

|

H

|

6200

|

6900

|

8000

|

8900

|

10750

|

11900

|

13000

|

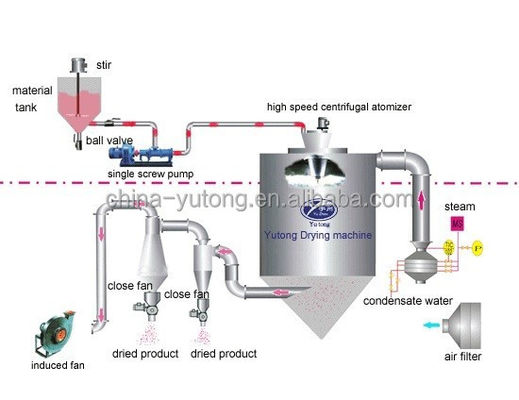

Description of Spray Dryer The machine adopts full close structure with primary middle and high effect air filter to fit one hundred thousand grade requirement, the tower body is provide cooling air jacket to make wall temperature less than80 degree, when the material stops on wall will not to be preheated and softened, it increases the powdercollection rate (95%) and will not appear mixing and sticking wall phenomenon.

Main Features 1)The tower body is equipped with cool air jacket to reduce inside tower temperature and eliminate productpreheating and soften phenomenon. 2)The atomizer on top of tower is equipped with cooling device to reduce atomizer temperature, at the sameeffectively eliminate material return to the top in eddy current and avoid preheat coking phenomenon. 3)Tower body and pipeline is equipped with manual quick-open cleaning hole and drainage hole. CIP auto- matic cleaning device can also equipped if needed. 4)A automatic control constant temperature feeding tank can be equipped. 5)Manual high pressure washing tools can be offered as accessories together with spray dryer.6)All product contact parts are made with Stainless Steel,(or whole parts with stainless steel)7) Product collect way adopts two grade cyclones and water film duster. 8) Air inlet temperature is automatic and continuous control which is interlocked with feeding.9)An air sweeping device can be optional for some produc

Q: Delivery period: A: Around 20-60 days, delivery perious will vary from different types of machin-ery,

Q: Payment of terms: A: Acceptable payment of terms: T/T, L/C, Cash after signing the contract, firstdeposit 30% of total as prepayment,and rest 70% after FAT but before shipment

Q: Quality Warranty: A: We guarantee all the machines are brand new, and we design and manufac-ture as per approbation by user; We guarantee every set of our machine after shipment is have guarantee period 15 months, during warranty period we will provide technician debuggingonsite, or free spare parts caused by the malfunction of machines. We guarantee we reply the user's bewilderment within 24 hrs after receive noti-fication.

Q: Package of merchandise: A: First pack with plastice membrane wrap on the surface of machines,external we use plywood case, finall load in container.

Q: What is service when we place an order with you? A: First we invite you to visit our factory, and negotiate the tecnnology andchoose model and type of machines for users, and give feasible advice of eachmaterial. Secondly we thank for you if you visit our factory to do FAT before shipment,give us your advice and we modify the machine if not meet the user's satisfac-tion. Last, we will dispatch at least 1 experienced and responsible technician togo to abroad for guide commissioning and train the operators. lf no need onsitecommissioning, we provide video guidance.

Q: Which information do you require then you could choose model subse-quently? A: We need to know the information as below: What is your material name? What is the initial moisture percentage before drying?What is the residual moisture percentage after drying? What is the heating temperature your material can undertake during dryingprocess? What is the heating source, steam, electricity, natural gas or others?Last but important, what is capacity how many kgs/h before drying or afterdrying?

Want to Know more details about this product