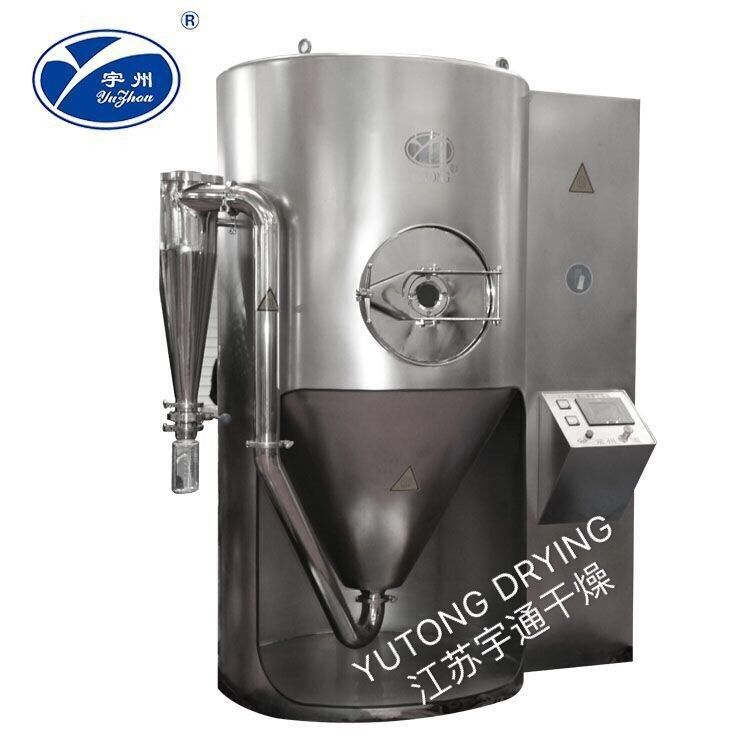

15kw Centrifugal Atomizer Spray Drying Machine For Amino Acid Powde

Product Details:

| Place of Origin: | Jiangsu, China |

| Brand Name: | Yuzhou Brand |

| Certification: | ISO9001:2008 |

| Model Number: | LPG-5 LPG-50 LPG-100 LPG-150 LPG-200 LPG-300 LPG-500 |

Payment & Shipping Terms:

| Price: | $98,000.00/Sets 1-99 Sets |

|---|---|

| Supply Ability: | 50 Set/Sets per Year |

|

Detail Information |

|||

| Type: | Spray Drying Equipment | Condition: | New |

|---|---|---|---|

| Voltage: | 220v/380v | Power: | 15kw |

| Dimension(L*W*H): | Varied | Warranty: | 1 Year |

| After-sales Service Provided: | Engineers Available To Service Machinery Overseas | Weight: | 6000KG |

| Application: | Pharmaceutical, Pigment, Chemical, Foodstuff, | Usage: | Reduce The Moisture And Make Powder |

| Capacity: | 5-1500 L Per Hour | Heating Source: | Steam+electricity |

| Port: | Shanghai | ||

| Highlight: | 15kw Spray Drying Machine,Centrifugal Atomizer Spray Drying Machine,Atomizer centrifugal dryer machine |

||

Product Description

Efficiency Centrifugal Atomizer Spray Drying Equipment For Amino Acid Powde

Outline:

1. Atomization: amomizing system must ensure a uniform distribution of the fog drops, which is crucial to ensure a good qualified rate of products.

2. Contact with hot airflow and fog drops: when enough hot air enters into drying tower, the direction and angle of hot air flaw have to be considerated, no matter cocurrent or mixed flow, must ensure the sufficient heat exchange, it is crucial.

Product Application

The centrifugal Spray Dryer is widely used technology in the liquid shaping technology and drying industry. It is suitable for producing powder, particle solid products from material of solution, emulsion, solidus and paste states. Therefore, when the particle size of the distribution final products, the residual water contents, the stocking density and the particles shape meet the precision standards, the centrifugal spray dryer is one of the most desired technologies.

Principle of work:

After filtering and heating, the air enter air distributor at the top of the dryer. The hot air enters the drying chamber in the spiral form uniformly. By passing through the high-speed centrifugal atomizer at the top of the tower, the material liquid will be rotated and sprayed into extremely fine mist liquid beads, through the very short time of contacting with hot air, the materials can be dried into the finished products. The finished products will be discharged continuously from the bottom of the drying tower and from cyclone separator. The waste gas emission by exhaust fan.

Main Features

1) High Speed of Drying, after the spraying of the material liquid, the surface area of material will be increased greatly. In the hot air flow, 95-98% of water can be evaporated at the moment. The time of completing the drying needs only several seconds. It is especially suitable for drying thermolabile ingredients.

2) At final products own the good uniformity, mobility, and dissolving capacity. And the final products are high in purity and good in quality.

3) The production procedure is simple and the operation control easy. The liquid with the moisture contents 40-60% (for special mterials, the content may reach 90%) can be dried into powder or particle products at a time. After the drying, there is no need for smashing and sorting, so as to reduce the operation procedures in the production and chance the product purity. The product particles diam enters, looseness and water contents can be adjusted through changing the operation condition in a certain scope, it is very convenient to carry out the control management.