Vacuum Harrow / Rake Rvd Rotary Drying Machine For Soybean Meals

Product Details:

| Place of Origin: | Jiangsu, China |

| Brand Name: | Yuzhou |

| Certification: | ISO14001 ISO9001 |

Payment & Shipping Terms:

| Price: | $13,800.00/Sets 1-9 Sets |

|---|---|

| Packaging Details: | plywood case. |

| Supply Ability: | 100 Set/Sets per Year Harrow Rake Dryer vacuum paddle dryer machine for soybean meals |

|

Detail Information |

|||

| Type: | Vacuum Drying Equipment | Drying Capacity (kg): | 100000kg |

|---|---|---|---|

| Application: | Medicine Processing, Chemicals Processing, Plastics Processing, Food Processing | Voltage: | Customized |

| Key Selling Points: | High Safety Level | After-sales Service Provided: | Online Support, Video Technical Support, Free Spare Parts, Field Installation, Commissioning And Training, Field Maintenance And Repair Service |

| After Warranty Service: | Video Technical Support, Online Support, Spare Parts, Field Maintenance And Repair Service | Material: | SUS304, SUS304L, SUS316, SUS316L, Ti, Other, SS304/SS316L |

| Name: | Harrow Rake Dryer Vacuum Harrow Dryer Machine For Soybean Meals | Heating Source: | Steam ,hot Water,oil |

| Highlight: | Harrow rotary drying machine,rvd rotary drying machine,rvd dryer |

||

Product Description

Harrow Rake Dryer Vacuum Harrow Dryer Machine For Soybean Meals Vacuum Drying Machine

Description

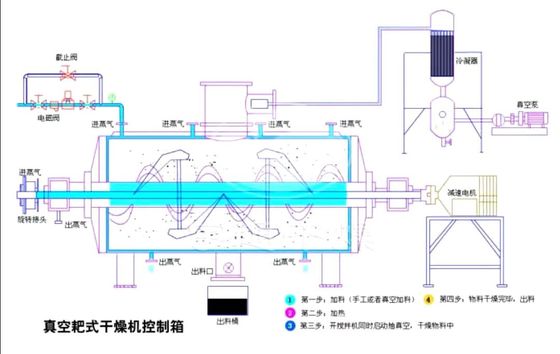

ZKG vacuum harrow drying equipment is new type high-efficiency horizontal vacuum drying equipment. It adopts jacketed structure,and the jacket can be heated by steam, hot water or conduction oil. The jacket transfers the heat to the inner wall of the shell via conduction or radiation. The dried materials are added into the dryer through an opening in the middle of the machine shell.Constant stirring of the revolving harrow causes the materials move back and forth. The surface contacting with the inner wall of the shell constantly updates, resulting in high drying rate and uniform finished products.

Application

ZKG vacuum harrow dryer equipment is designed for drying slurry, pasty, powdery materials, thermosensitive materials requiring low-temperature drying, easily oxidized materials, as well as explosive materials, toxic materials and the materials whose organicsolvents should be recovered. This vacuum drying equipment is applied to the pharmaceutical, nourishment, food, chemical and other industries.

Features

1. ZKG vacuum harrow drying equipment uses large-area interlayer heating, which can obtain large heat-transfer surface and high heat efficiency.

2. This vacuum drying equipment with a stirring device can improve the heating uniformity and smoothly dry slurry and pasty materials.

3. It is easy to operate and clean, which can effectively reduce labor intensity.

4. If this vacuum harrow dryer adopts internal concurrent heating, the heating area will be greatly increased.

Description

ZKG vacuum harrow drying equipment is new type high-efficiency horizontal vacuum drying equipment. It adopts jacketed structure,and the jacket can be heated by steam, hot water or conduction oil. The jacket transfers the heat to the inner wall of the shell via conduction or radiation. The dried materials are added into the dryer through an opening in the middle of the machine shell.Constant stirring of the revolving harrow causes the materials move back and forth. The surface contacting with the inner wall of the shell constantly updates, resulting in high drying rate and uniform finished products.

Application

ZKG vacuum harrow dryer equipment is designed for drying slurry, pasty, powdery materials, thermosensitive materials requiring low-temperature drying, easily oxidized materials, as well as explosive materials, toxic materials and the materials whose organicsolvents should be recovered. This vacuum drying equipment is applied to the pharmaceutical, nourishment, food, chemical and other industries.

Features

1. ZKG vacuum harrow drying equipment uses large-area interlayer heating, which can obtain large heat-transfer surface and high heat efficiency.

2. This vacuum drying equipment with a stirring device can improve the heating uniformity and smoothly dry slurry and pasty materials.

3. It is easy to operate and clean, which can effectively reduce labor intensity.

4. If this vacuum harrow dryer adopts internal concurrent heating, the heating area will be greatly increased.

Company Profile

FAQ

1. Why i can believe Yutong?with more than 20 year experience 150 workers 16000 square meter.expertise technical team we can make scheme as u as u requirement

with IS01990 1S014001 CE...

2. what about the after service , if i can do not use machine well, what will u do?

Please do not worry we will arrange technical staff come scene help u debugging and will train u by free.

with IS01990 1S014001 CE...

2. what about the after service , if i can do not use machine well, what will u do?

Please do not worry we will arrange technical staff come scene help u debugging and will train u by free.

3. How can i choose model

please tell me material name,capacity input.bulk density, organic solution or not heat source max drying temperature then i can make scheme as u requirement.

Want to Know more details about this product