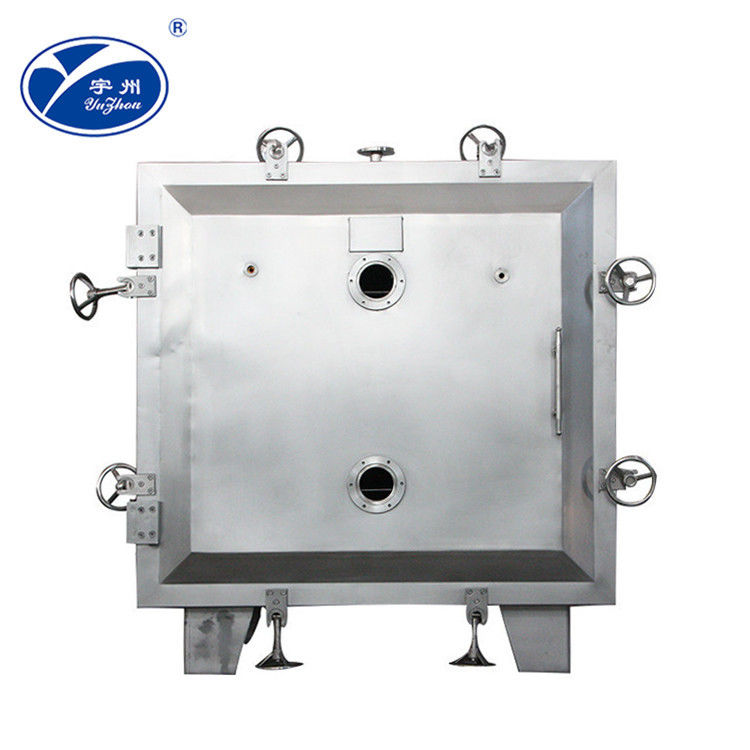

Cesium Acetate 0.784Mpa Vacuum Drying Machine SS304 / SS316L

Product Details:

| Place of Origin: | Jiangsu, China |

| Brand Name: | Yuzhou |

| Certification: | ISO14001 ISO9001 |

Payment & Shipping Terms:

| Price: | $12,000.00/Sets 1-9 Sets |

|---|---|

| Packaging Details: | wooden packing . Special fumigation -free wooden material . Or according to customer requirement . |

| Supply Ability: | 100 Set/Sets per Year YZG Series Cesium acetate Dryer Drying Equipment |

|

Detail Information |

|||

| Type: | Vacuum Drying Equipment | Application: | Medicine Processing, Chemicals Processing, Plastics Processing, Food Processing |

|---|---|---|---|

| Voltage: | Customized | Key Selling Points: | High Safety Level |

| Material: | SS304/SS316L | Heating Source: | Electrical,steam Or Otheres |

| Highlight: | Cesium Acetate Vacuum Drying Machine,SS304 Vacuum Drying Machine,SS316L chemical drying equipment |

||

Product Description

YZG Chemicals Processing Customized Series Cesium Acetate Dryer Drying Equipment

Description:

Vacuum drying refers to dry the materials under vacuum condition, and use vacuum pump to extract air and wet, thus accelerating drying rate. YZG round vacuum dryer and FZG square vacuum dryer belong to static vacuum drying machine. Under vacuum conditions, the boiling point of material solvent is reduced, making this machine to dry unstable or thermosensitive materials. Additionally, the vacuum dryers have excellent sealing ability, so they are also used for drying the materials requiring solvent recovery or materials with poisonous gas.

Application:

YZG round vacuum dryers and FZG square vacuum dryers are widely used in the pharmaceutical, nourishment, food, chemical, dyes, electronics and other industries. Our vacuum drying machines accord with the requirements of GMP standards.

Features:

1. Before drying, it can carry out disinfection treatment, and the drying process is with no impurity.

2. Our static vacuum drying machine can get relatively higher drying rate at low temperature, and it can make full use of the heat.

3. YZG round vacuum dryer is a kind of static vacuum dryer, which will not damage the shape of the material.

Technical Parameters of Vacuum Drying Machine

| Model | YZG-600 | YZG-1000 | YZG-1400A | FZG-8 | FZG-15 | FZG-30 | FZG-38 |

| Internal Size of Drying Oven (mm) | 600 × 976 | 1000 × 1527 | 1400 × 2054 | 730 × 1200 × 1450 | 1500 × 1400 × 1220 | 2200 × 1500 × 1500 | 2200 × 1500 × 1600 |

| External Size Of Drying Oven (mm) | 1135 × 810 × 1020 | 1693 × 1190 × 1500 | 2386 × 1675 × 1920 | 930 × 1380 × 1540 | 1513 × 1924 × 2060 | 2400 × 1680 × 2050 | 2400 × 1680 × 2250 |

| Layers of Drying Rack | 4 | 6 | 8 | 8 | 8 | 8 | 10 |

| Interlayer Distance (mm) | 81 | 102 | 102 | 122 | 122 | 122 | 122 |

| Size of Drying Tray (mm) | 310 × 600 × 45 | 250 × 410 × 45 | 400 × 600 × 45 | 460 × 640 × 45 | 460 × 640 × 45 | 460 × 640 × 45 | 460 × 640 × 45 |

| Drying Tray Number | 4 | 12 | 32 | 16 | 32 | 64 | 80 |

| Pressure of Drying Rack Tube (Mpa) | ≤ 0.784 | ||||||

| Temperature of Drying Rack (ºC) | -35 to 150 | ||||||

| No-load Vacuum degree within the tank (Mpa) | -0.09 to 0.096 | ||||||

| Weight of drying oven (kg) | 250 | 800 | 1400 | 1680 | 2100 | 2850 | 3200 |

![]()

Company introcuction

![]()

1.We use high-end imported brands of instruments and processing machines, to create superior quality machine for you ; yutong makes you feel free about the after-sales service.

2.We provide the spare parts with the cost of the spare parts themselves for life long time .

3.We can make the machine based on the customer requirements .

4.We have strong team ,and can help customer to design his process of the product .

5.Guarantee /warranty :1year. calculating from the day of successful installation and commissioning.

Factory inside

![]()

![]()

Processing&Our team

![]()

Service

Pre-service

Introduce the product to the customer in detail,answer the question raised by customer carefully;

Sale service

1.Ensure product with high quality and pre-commissioning before delivery;

2.Delivery on time;

3.Provide full set of documents as customer’s requirements.

After-sale service

Provide considerate services to minimize clients’ worries.

1.Assist clients to prepare for the first construction scheme;

2.Install and debug the equipment;

3.Train the first-line operators;

4. Examine the equipment;5.Take initiative to eliminate the troubles rapidly;

6.Provide technical support;

7.Establish long-term and friendly relationship.

Service commitment

1. Provide clients one-year warranty to make sure the machine work well;

2.We always keep certain inventory level of spare parts, which means the replacements can be sent to you timely;

3.Send every client a preferential quotation.

Centrificate

![]()

Exhibition

![]()

![]()

FAQ

1.Are you a manufacturer ,trading company or a third party

We are a manufacturer ,we set in 2000.

2.Where is your factory located

Our company is located in Changzhou city ,Jiansu province,China .it is In the middle of Shanghai and nanjing