SXG-20 Series Cellulose Spin Flash Dryer Fluid Bed Drying Equipment

Product Details:

| Place of Origin: | Jiangsu, China |

| Brand Name: | Yuzhou, Yuzhou |

| Certification: | ISO9001:2008 |

| Model Number: | SXG |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | inner film package<br>outer plywood package |

| Delivery Time: | 45-90days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 50 Set/Sets per Year |

|

Detail Information |

|||

| Type: | Fluid Bed Drying Equipment | Voltage: | 220-440V |

|---|---|---|---|

| After-sales Service Provided: | Engineers Available To Service Machinery Overseas | Application: | Chemical,pharmaceutical,food,plastic,oil,slag,salt, |

| Heating Source: | Steam,electricity,gas,oil | Capacity: | Design According To Customer Requirement |

| Product Name: | SXG Series High-Speed Rotating Dryer In Foodstuff Industry | Usage: | Drying Grinding Sieve |

| Installation: | Engineer Guide | Manufacturer: | Jiangsu Yutong Drying Engineering Co., Ltd |

| Highlight: | Cellulose Spin Flash Dryer,SXG-20 Cellulose Flash Dryer,Fluid Bed Spin Flash Dryer |

||

Product Description

Directly Sale Wholesale Price SXG-20 Series Cellulose Flash Dryer

Description:

SXG Series rotating drier is developed by our company, and its technology is based on advanced techinology adored. The machine includes many superiority, such as reasonable design, compact stuction, widly utilization, great productive capacity, good quality, high effect and save energy, drying, grinding and sieve are completely in one equipment in once time. It eliminates pollution and the technology is reached international advance level. Flash drying machine has the original bearing induction cooling (water cooling), oil pump design with connection to send oil lubrication, cooling the bearing, seal performance, on the spindle design uses a half ring, motor using speed regulation, smooth transmission, low noise, the service life is ten times of similiar products.

Principle:

The hot air enters into the bottom of the drier in tangent direction. Under the driving of the stirrer, a powerful rotating wind field is formed. The paste state materials enter into the drier through the screw charger. Under teh powerful function of the stirring vanes at high-speed rotation, the materials are distributed under the function of strike, friction and shearing force. The block state mate-rials will soon be smashed and contact the hot air fully and the materials are heated and dried. The dried materials after the dewatering will go up with the heatair flow. The step rings will stop and keep the big particles. Small particles will be discharged out of the drier from the ring center and will be restored by the whirl separator and dust remover. The hot fully dried or big piece materials will be sent to the wall of the equipment by centrifugal force function and be smashed again after they fall down to the botto

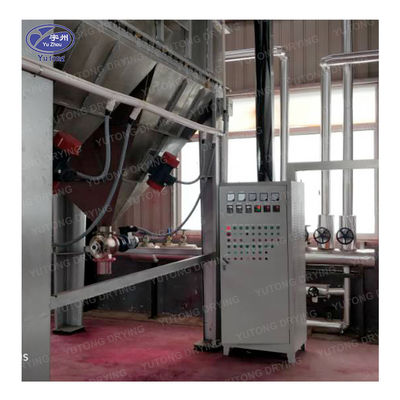

Jiangsu Yutong Manufacture facilities:

![]()

![]()

Outer plywood case package

Pre-service

Act as a good adviser and assistant of clients to enable them get rich and generous returns on their investments.

1. Introduce the product to the customer in detail, answer the question raised by customer carefully;

2.Make plans for choice according to the needs and special requirements of users in different sectors;

Sale service

1. Ensure product with high quality and pre-commissioning before delivery;

2. Delivery on time;

3.Provide full set of documents meet customer’s requirements.

After-sale service

Provide considerate services to minimize clients’ worries.

1.Assist clients to prepare for the first construction scheme;

2.Install and debug the equipment;

3.Train the first-line operators;

4. Examine the equipment;

5.Take initiative to eliminate the troubles rapidly;

6.Provide technical support;

7.Establish long-term and friendly relationship.

Service commitment

1. Provide clients one-year warranty to make sure the machine work well;

2.We always keep certain inventory level of spare parts, which means the replacements can be sent to you timely;

FAQ

1. Q: Jiangsu Yutong Drying Engineering Co., Ltd is a manufacturer, trading company or a third party?

A: We are a manufacturer, Yutong company established in 2000.

2. Q: Where is your factory located?

A: Yutong is located in Changzhou city, Jiansu province, China. it is In the middle of Shanghai and Nanjing.

3. Q: How can I go to your factory?

A: You can fly to shanghai Pudong or Hongqiao international airport directly, then take the high speed train to Changzhou station (just 1 hour from Shanghai to Changzhou by train) and we arrange to pick you up at Changzhou station to go to our company. Yutong company is around 30km away from Changzhou station.

If you are in China now, you can fly to Changzhou Benniu airport, or take train or bus to Changzhou city directly .

We sincerely welcome to visit our company at any time.

Principle of work matters that should be known before order:

1. What is product name?

2. How many kgs per hour before drying OR after drying?

3. How about the initial moisture content % before drying?

4. How about the initial moisture content % before drying?

5. Permissible residual water contents & after drying?

6. Control requirement: how many celcius the inlet air temperature need to be controlled?

7. How about outlet air temperature?

8. Energy that can be supplied: steam pressure supply capacity, electricity capacity, fuel coal, oil and air capacity?

9. Collecting powder method is bag filter or second cyclone?

10. Other special requirements, such as brand name of accessories, motor, decelerator, bearing; etc.

Contact information:

Annie Shi (Foreign Trade Executive)

Whatsapp/Wechat/Mobile: +86 15861862227

Skype: annieshi2012

Email: 1442341010 AT qq.com

Email: jsyutongdry AT hotmail.com

Jiangsu Yutong Drying Engineering Co., Ltd

Address: No. 68, Shunhe Road, Zhenglu Town, Changzhou City, 213116, Jiangsu China