400V Gyratory Screen Separator , Circular Flour Sieve Machine

Product Details:

| Place of Origin: | China |

| Certification: | SGS CE ISO |

| Model Number: | RFT |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1units |

|---|---|

| Price: | USD1490-9900 per unit |

| Packaging Details: | plywood |

| Delivery Time: | 7 working days |

| Payment Terms: | Western Union, MoneyGram |

| Supply Ability: | 10000units per year |

|

Detail Information |

|||

| Name: | Circular Vibrating Screen | Application: | Power, Granule , Liquid |

|---|---|---|---|

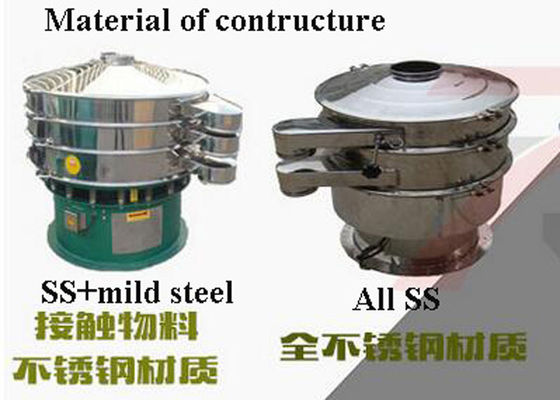

| Layer: | 1-4layers | Material: | Stainless Steel 304 Or 316L |

| Application Industries: | Food, Chemical, Pharma, Etc | Voltage: | 110 220 380 400 415 |

| Highlight: | 400V gyratory screen separator,Circular flour sieve machine |

||

Product Description

Circular Flour Sieve Machine , High Efficient Gyratory Screen Separator

Working principle of circular vibrating screen: RTF series circular vibrating screen is a single-axis circular motion inertial vibrating screen. When the circular vibrating screen is operated by inertial motor, the inertial force generated by the eccentric block forces the screen box to vibrate and is added to the screen surface of the sieve machine. The material produces a throwing motion, so that particles of a certain size are passed through the mesh to achieve a screening operation.

Since the vibrator is arranged above the center of gravity of the screen box, the elliptical long axis at both ends of the screen box is formed into a lower figure-shaped shape, and the upper end of the elliptical long axis of the feeding end is oriented toward the discharge direction, which is advantageous for quickly dispersing the material on the box machine. The upper end of the elliptical long axis of the discharge end is opposite to the discharge direction, which reduces the moving speed of the material, which is beneficial to the screening of the difficult-to-screen material, and the arc-shaped screen surface increases the effective area of the sieve machine, thereby increasing the productivity.

| Model | Layer | Power(KW) | Mesh diameter(mm) | Dimension(mm) |

| RFT-400 | 1S | 0.18 or 0.37 | 360 | 720x430x600 |

| 2S | 720x430x690 | |||

| 720x430x780 | ||||

| 3S | ||||

| RFT-600 | 1S | 0.37 or 0.55 | 560 | 600x600x740 |

| 2S | 600x600x880 | |||

| 3S | 600x600x1020 | |||

| RFT-800 | 1S | 0.55 or 0.75 | 760 | 800x800x840 |

| 2S | 800x800x1000 | |||

| 3S | 800x800x1160 | |||

| RFT-1000 | 1S | 0.75 or 1.1 | 930 | 970x970x950 |

| 2S | 970x970x1110 | |||

| 3S | 970x970x1270 | |||

| RFT-1200 | 1S | 1.1 or 1.75 | 1130 | 1170x1170x1090 |

| 2S | 1170x1170x1250 | |||

| 3S | 1170x1170x1410 | |||

| RFT-1500 | 1S | 1.5 or 2.2 | 1430 | 1470x1470x1110 |

| 2S | 1470x1470x1270 | |||

| 3S | 1470x1470x1430 |