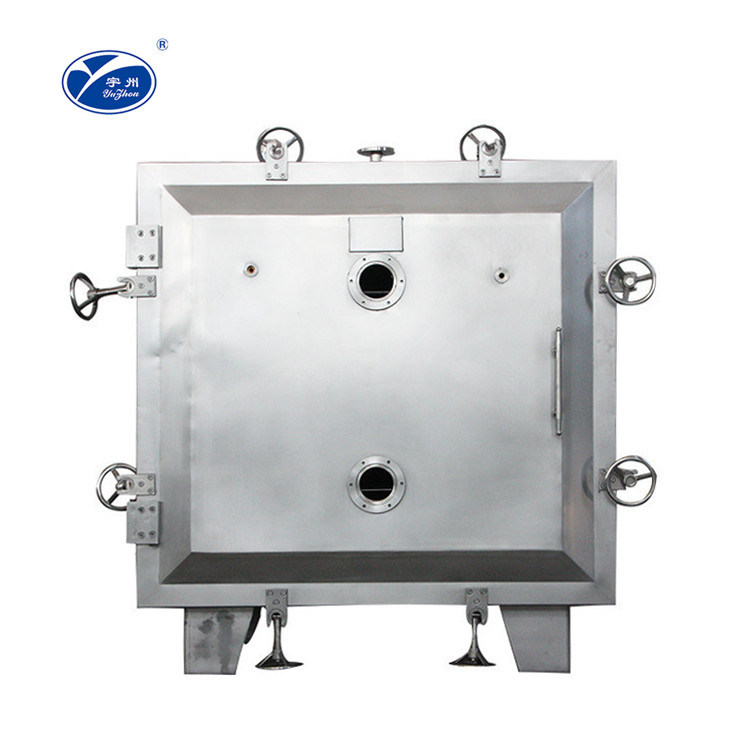

96 trays SUS304 Industrial Vacuum Dryer Pharmaceutical Use

Product Details:

| Place of Origin: | China |

| Brand Name: | YUTONG |

| Certification: | SGS, CE, ISO |

| Model Number: | FZG |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1unit |

|---|---|

| Price: | USD10990-59000/unit |

| Packaging Details: | shipping container |

| Delivery Time: | 35 working days |

| Payment Terms: | L/C, D/A, D/P, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 1000unit per year |

|

Detail Information |

|||

| Name: | Vacuum Tray Dryer | Material: | SUS 304, SUS316L |

|---|---|---|---|

| Type: | Static Drying | Tray Number: | 8-96 |

| Heating Source: | Electricity, Hot Water Or Steam | Packing: | 40HQ Container |

| Purpose: | Pharmaceutical Drying | ||

| Highlight: | 96trays Industrial Vacuum Dryer,SUS304 Industrial Vacuum Dryer |

||

Product Description

Pharmaceutical Industrial Vacuum Dryer SUS 304 Energy Saving Long Service Life

Introduce of Yzg/fzg industrial vacuum dryer

Principle

The so-called vacuum drying, is the drying material in the vacuum conditions, heating and drying, if the use of vacuum pump to wet, the drying rate is accelerated.

Note: If the condenser is used, the solvent in the material can be recycled through the condenser, such as the use of SK series water ring vacuum pump or ZSWJ series hydraulic injection vacuum pump unit, can not use the condenser, save investment.

Application

Industrial vacuum dryer suitable for low temperature drying of heat-sensitive materials with easy decomposition, polymerization or deterioration at high temperature, and is widely used in pharmaceutical, chemical, food and electronics industries, such as tablet drying, pills, API powder and other medicine powder drying.

Characteristics

The boiling point of the material solution under vacuum decreases, so that the heat transfer force of the evaporator increases, so the heat transfer area of the evaporator can be saved by certain heat transfer.

The heat source of evaporation operation can use low pressure steam or waste heat steam and hot water cycle.

Less heat loss of evaporator

Before drying can be disinfected, drying process without any impurities mixed, in line with the GMP requirements. belongs to the static vacuum dryer, so the shape of the dry material will not be damaged.

Techinical specification:

| Model Name | YZG-600 | YZG-800 | YZG-1000 | YZG-1400A | FZG-10 | FZG-15 | FZG-20 | |

| Inter size of drying chamber(mm) | Φ600×976 | Φ800×1247 | Φ1000×1527 | Φ1400×2054 | 1500×1060 ×1220 | 1500×1400 ×1220 | 1500×1800 ×1220 | |

| Outer size of drying chamber(mm) | 1135×810 ×1024 | 1700×1045 ×1335 | 1693×1190 ×150 | 2386×1675 ×1920 | 1513×1924 ×1720 | 1513×1924 ×2060 | 1513×1924 ×2500 | |

| Layers of baking support | 4 | 4 | 6 | 8 | 5 | 8 | 12 | |

| Interval of baking(mm) | 82 | 82 | 102 | 102 | 122 | 122 | 122 | |

| Size of baking tray(mm) | 310×600 ×45 | 520×410 ×45 | 520×410 ×45 | 460×640 ×45 | 460×640 ×45 | 460×640 ×45 | 460×640 ×45 | |

| Quantity of baking tray | 4 | 8 | 12 | 32 | 20 | 32 | 48 | |

| working pressure inside the pipe of baking support(Mpa) | ≤0.784 | ≤0.784 | ≤0.784 | ≤0.784 | ≤0.784 | ≤0.784 | ≤0.784 | |

| Operation temperature of baking support, oC | 35-150 | 35-150 | 35-150 | 35-150 | 35-150 | 35-150 | 35-150 | |

| Degree of vacuum inside the chamber when operation (Mpa) | -0.09~0.096 | |||||||

| Under the condition of -0.1Mpa and 110oC,evaporation rate of water(kg/m2.hr ) | 7.2 | 7.2 | 7.2 | 7.2 | 7.2 | 7.2 | 7.2 | |

| When condenser is used,Model,and power of vacuum pump(kw) | 2X-15A 2KW | 2X-30A 3KW | 2X-30A 3KW | 2X-70A 5.5KW | 2X-70A 5.5KW | 2X-70A 5.5KW | 2X-90A 2KW | |

| When condenser is not used,Model,and power of vacuum pump(kw) | SK-0.8 2.2KW | SK-2.7 4KW | SK-3 5.5KW | SK-6 11KW | SK-3 5.5KW | SK-6 11KW | SK-6 11KW | |

| Weight of drying chamber(kg ) | 250 | 600 | 800 | 1400 | 1400 | 2100 | 3200 | |