1-3mm Cylinder Granules Revolving Granulator , SUS316L Extruder Granulator

Product Details:

| Place of Origin: | China |

| Certification: | SGS CE ISO |

| Model Number: | ZL |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1units |

|---|---|

| Price: | USD2900-3890 per unit |

| Packaging Details: | plywood or shipping container |

| Delivery Time: | 25 working days |

| Payment Terms: | Western Union, MoneyGram, D/A, L/C, D/P, T/T |

| Supply Ability: | 1000units per year |

|

Detail Information |

|||

| Material: | SUS304 SUS316L Food Grade GMP | Standard: | GMP |

|---|---|---|---|

| Product: | Cylinder Granules | Cutter: | Speed Viable |

| Color: | Stainless Steel | Voltage: | 380V 220V |

| Granule/pellet Size: | 1-3mm Cylinder Granules | ||

| Highlight: | 3mm Revolving Granulator,SUS316L extruder granulator |

||

Product Description

High Speed Revolving Granulator Food Grade Stainless Steel Stable Performance

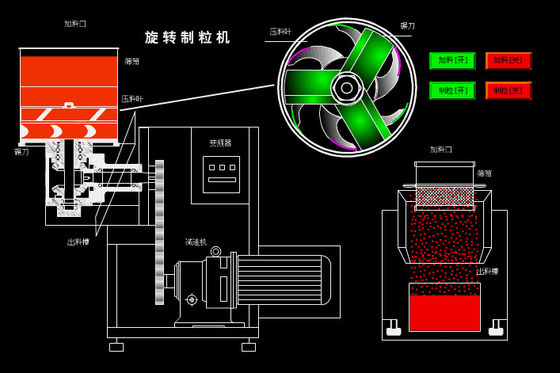

ZL series revolving granulator

Pesticide water dispersible granule (WDG) production equipment

Pesticide water dispersible granules were developed in the 1980s as a new dosage form. Because of its good safety, no pollution to the environment, and the advantages of traditional pesticide formulations, it is considered to be an important direction for the development of pesticide formulations. WDG has become one of the most promising products in a new generation of pesticide formulations. Water-dispersible granules are a new pesticide formulation developed in Europe and the United States in the early 1980s. Also known as dry suspension, the International Federation of Pesticide Industry Associations (GIFAR) defines it as: particles used after disintegration and dispersion in water. Agent. The water-dispersible granule is mainly composed of an active ingredient of a pesticide, a dispersing agent, a wetting agent, a binder, a disintegrating agent and a filler, and has a particle diameter of 200 μm to 5 mm, and can rapidly disintegrate and disperse after entering water to form a high suspension dispersion system.

Rotary revolving granulator advantages:

3.1.1 This machine is equipped with variable frequency speed regulation, with special air-cooling device, which can effectively and uniformly cool the whole granulating screen and granulating knife and materials, avoiding local cooling and blocking the mesh, and granulating the viscous and heat-sensitive materials. Cooling and separation are obtained, and the chassis is provided with a water cooling device.

3.1.2 This machine adopts double seal at both the granulating knife and the pressing knife to reduce the dust and foreign matter from entering the body of the deceleration chassis and biting the bearing.

3.1.3 Using a special-shaped grinding knife to improve the processing technology of the granulating knife, thereby reducing the heat of the material and reducing the pressing force between the knife and the screen, thereby prolonging the service life of the screen.

3.1.4 The machine is easy to discharge, no need to manually clean, can automatically discharge. Save labor costs.

3.1.5 Simultaneously improve the structure of the reducer and the structure of the whole body, so that the machine has less noise during operation, stable operation and compact structure.

Technical Parameter

Size of milling knife(mm) |

JLZ-80 | JLZ-300 | JZL-350 |

| Diameter of granule(mm) | Φ0.8-3.0 (it may be in accordance with the requirements of costomers) |

Φ.8-3.0 (it may be in accordance with the requirements of costomers) |

Φ.8-3.0 (it may be in accordance with the requirements of costomers) |

| Overall dimesions(mm) | 450×300×450 | 880×640×1200 | 1300×800×1400 |

| Power of motor (kw) |

0.18 | 5.5 | 11 |

| Weight(kg) | 25 | 400 | 780 |

Production capcity(kg/h) |

1-10 |

100-300 | 250-600 |

Note:Becaise the rae materials exist in difference,the output in the table is for reference only.]