Granule Fluidized Bed Processor , SGS 50-120KG /Second-rate Pharmaceutical Dryer Machine

Product Details:

| Place of Origin: | China |

| Certification: | SGS, CE, ISO |

| Model Number: | GFG |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1unit |

|---|---|

| Price: | USD10990-59000/unit |

| Packaging Details: | shipping container |

| Delivery Time: | 35 working days |

| Payment Terms: | L/C, D/A, D/P, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 1000unit per year |

|

Detail Information |

|||

| Name: | Fluid Bed Dryer/ Fluidized Bed Dryer | Material: | SUS 304, SUS316L |

|---|---|---|---|

| Temperature: | 30-200℃ | Evaporation Capacity: | 50-120KG/Second-rate |

| Heating Source: | Electricity Or Steam | Packing: | 40HQ Container |

| Standard: | GMP | Application: | Wet Powder Or Granules |

| Highlight: | 50KG/H fluidized bed processor,SGS fluidized bed processor,120KG/H pharmaceutical dryer machine |

||

Product Description

Granule & Powder Fluid Bed Dryer In Pharmaceutical , Fluidized Bed Processor Easy To Operate

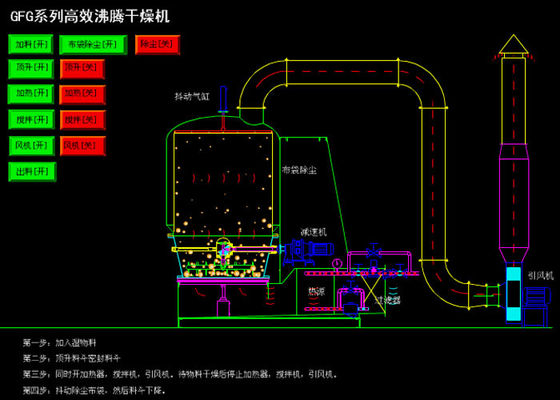

Working principle

After the air is purified by heating, it is introduced from the lower part by the induced draft fan and passes through the hole mesh plate of the hopper. In the working chamber, fluidization is formed by stirring and negative pressure, and the water is quickly evaporated and then taken away with the exhaust gas, and the material is quickly dried.

Features

The fluidized bed dryer has a circular structure to avoid dead ends.

The hopper is set to agitate to avoid agglomeration of wet materials and formation of a ditch during drying.

The use of tumbling and unloading is convenient and rapid, and the automatic feeding and discharging system can be designed according to requirements.

The seal is operated under negative pressure and the gas stream is filtered. It is easy to operate and easy to clean. It is an ideal equipment that meets the requirements of “GMP”.

The drying speed is fast and the temperature is symmetrical. The drying time of each batch is generally 20-30 minutes.

Application range

Mechanism screw extrusion particles, rocking particles, wet high speed mixing granulation particles.

Wet granules and powdery materials in the fields of medicine, food, feed, and chemical industry are dry.

Large granular, small, viscous, granular material.

Konjac, polyacrylamide and other materials that change in volume when dried.

Equipment composition

1, the skip

2, control valve

3, initial effect filter

4, sub-high efficiency filter

5, heater

6, liquid pump

7, induced draft fan

Composition chart

Composition chart

8, silencer

Models and parameter

| Item | Model | |||||||||

| GFG-60 | GFG-100 | GFG-120 | GFG-150 | GFG-200 | GFG-250 | GFG-300 | ||||

| Volume of hopper | Liter | 200 | 300 | 400 | 500 | 650 | 800 | 1000 | ||

| Production capacity | kg/batch | 30-60 | 50-100 | 60-120 | 70-150 | 100-200 | 120-250 | 150-300 | ||

| Air inlet temperature | 0C | 50-100 | ||||||||

| Fan | Blast | M3/h | 2576 | 3488 | 3619 | 5114 | 5153 | 6032 | 7185 | 7766 |

| Air pressure | Pa | 5639 | 5080 | 7109 | 5869 | 9055 | 7610 | 7400 | 7218 | |

| Motor power | kw | 7.5 | 11 | 11 | 15 | 18.5 | 22 | 22 | 30 | |

| Agitator | Speed | r/min | 11 | 11 | 11 | 11 | 11 | 11 | 11 | |

| Motor power | kw | 0.55 | 1.1 | 1.1 | 1.5 | 1.5 | 2.2 | 2.2 | ||

| Steam | Pressure | Mpa | 0.4 | 0.4 | 0.4 | 0.4 | 0.6 | 0.6 | 0.6 | |

| Consumption | kg/h | 140 | 170 | 210 | 240 | 230 | 280 | 280 | ||

| Compressed air | Pressure | Mpa | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | |

| Consumption | m3/h | 0.6 | 0.6 | 0.6 | 0.9 | 0.9 | 0.9 | 0.9 | ||

| Weight of main frame | kg | 1000 | 1200 | 1200 | 1500 | 1700 | 2000 |

2200

|

||