Double Screw 0.3-10m3 Powder Mixer Machine Fertilizer Mixing Use

Product Details:

| Place of Origin: | China |

| Certification: | SGS ISO CE |

| Model Number: | ZH |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1units |

|---|---|

| Price: | USD1490-9890 per unit |

| Packaging Details: | plywood or container |

| Delivery Time: | 25 working days |

| Payment Terms: | Western Union, MoneyGram |

| Supply Ability: | 1000units per year |

|

Detail Information |

|||

| Material: | Stainless Steel 304 Or 316L | Structure: | Double Screw |

|---|---|---|---|

| Rotary: | Yes | Application: | Food/pharmaceutical Insudstries |

| Applicable To: | Powder | Standard: | GMP |

| Highlight: | 0.3m3 Powder Mixer Machine,10m3 Powder Mixer Machine |

||

Product Description

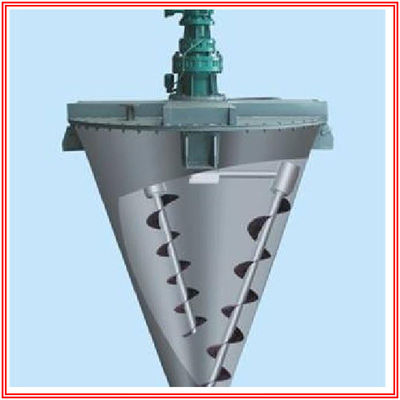

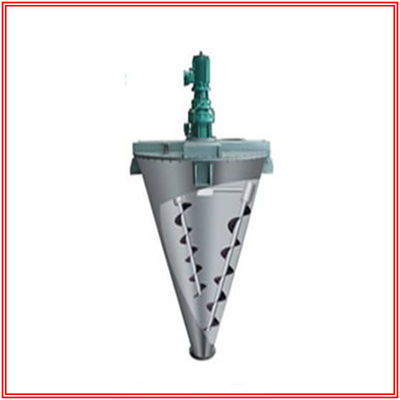

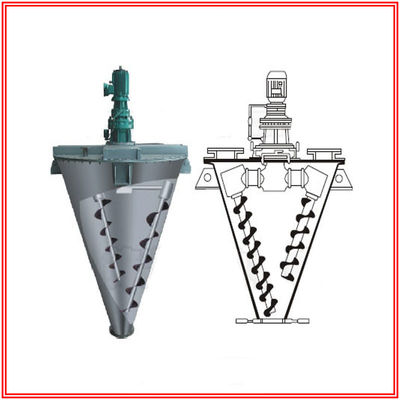

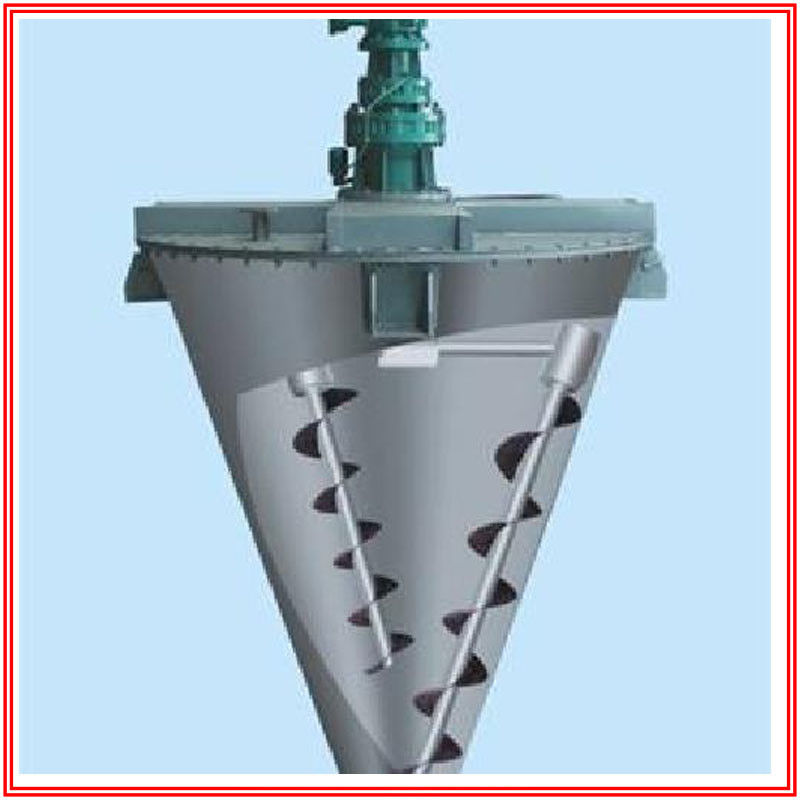

Double Screw Powder Mixer Machine For Chemical Powder Mixing Big Capacity

First, the product uses:

This machine is widely used in chemical, fertilizer, oil fields, oil refineries, pesticides, veterinary drugs, paints, pigments, dyes, metallurgy, metallurgy, refractory, mining, building materials, electronics, plastics, feed, aquaculture, pharmaceutical, biotechnology, food, solid health care products, ceramics, glass and new materials, nuclear materials, and many other industries - solid mixing, solid - liquid mixing, liquid - liquid mixing. The machine wide adaptability mixture, mixing heat-sensitive materials composition does not produce segregation phenomenon of mixed coarse, fine and ultra-fine powder of various particles, fibers or sheet material has good adaptability .

Second, the principle:

Rapid rotation mixer consists of two asymmetric spiral sheet material upward, forming two shares asymmetric tube arm from the bottom up along the spiral stream. Boom driven spiral revolution, so that different degrees of material into the spiral outer envelope of the stud. Part of the material are staggered lift, another part of the material was thrown stud, so as to constantly update the proliferation of full-circle orientation materials, be referred to the upper portion of the material in the two strands converge toward the center of the pocket formed generally downward stream, supplement bottom of the hole, so as to form convection circulation. Due to the complexity of the motion, the material in a relatively short time to obtain a homogeneous mix, a higher degree of mixing.

| specx | unit | DSH0.3 | DSH0.5 | DSH1 | DSH2 | DSH4 | DSH6 | DSH10 |

| total volume | (m3) | 0.3 | 0.5 | 1 | 2 | 4 | 6 | 10 |

| feeding rate | 0.4-0.6 | |||||||

| diameter of materials to be mixed | (um) 40-3000 | |||||||

| operation condition | Ambient temperature,normal pressure,sealed to dust | |||||||

| production capacity p=1g/cm3 | (kg) | 180 | 300 | 600 | 1200 | 2400 | 3600 | 6000 |

| power | (kw) | 2.2 | 2.2 | 5.5 | 5.5 | 11 | 20.7 | 30.7 |

| time of mixing | (min) 4-10(special material to be determined by trial) | |||||||

| weight | (kg) | 500 | 1000 | 1200 | 1500 | 2800 | 3500 | 4500 |

Relaed Products

Want to Know more details about this product